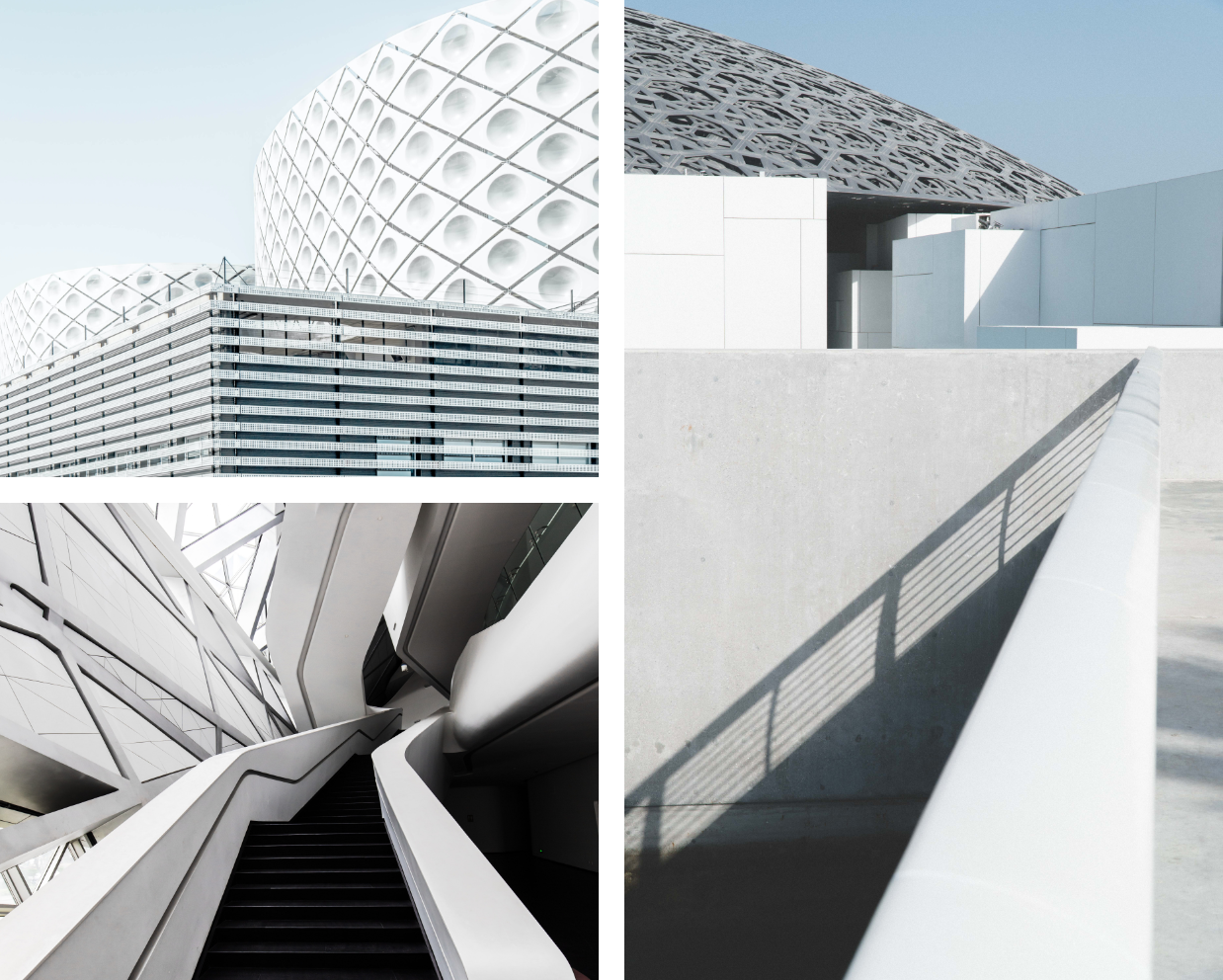

Architectural trend:

colourful white cement

ArchitectureCemix ProWhite is high standards in the production of coloured concrete for individual solutions. No wonder – thanks to its light inherent colour, Cemix ProWhite after all enables impressive results and a wide range of pastel colours even with small amounts of pigment.

The play of light and shade also takes Cemix ProWhite to another level, especially after the surfaces have been moulded. A further enhanced appearance, particularly on light-coloured concrete surfaces. In other words, when constructing, Cemix ProWhite is the excellent choice for those who want to experience unique brilliance and splendid colours instead of gray concrete surfaces.

Excellent properties thanks to high-quality minerals

Why white cementWhite cement makes it possible to produce snow-white surfaces. If it is completely dyed, it can be used to manufacture significantly more brilliant colours than with grey cement. But white cement also leaves nothing to be desired in terms of strength and durability. The same strength classes can be achieved as with best types of grey cement. And also, when it comes to the use of concrete aggregates, all options are open to you.

The main components for the production are high-quality limestone and white clay kaolin. In our quarry near the plant, we produce special limestone with a minimum content of colouring agents. The second main raw material, kaolin, comes from our Plast quarry, the largest kaolin deposit in Russia. Using our own sources guarantees a consistently high whiteness and strength.

Overview of advantages

Advantages- White cement is a good reflector to the light.

- Products of white cement can be recycled and reused in other products.

- White cement can be used instead of white paint or other whitewash material.

- It can be used to set the top roof and street pavers, marble and ceramic tiles.

- White cement can be applied as wall putty in order to fill the uneven surface.

- Ideal for the production of concretes and mixtures with high waterproofing properties.

- White cement products are non-combustible and fire-safe.

- White cement products do not require any additional finishing because you can create a surface with decorative properties from the outset

- White cement is finely ground and has a high strength, which creates a dense cement matrix, with high environmental protection properties.

- White cement is finely ground and has a high strength, which enables it to be used to create high-strength concrete and reinforced concrete products.